Silkscreen Printing

Why Choose LL Potters?

If you’re going to get the most out of silk screen printing, then you’ll need to work with leading experts in the field. Luckily, you have come to just the right place for that! Many Potters customers take advantage of the fact that we have our own “In house” silk screening facility. It enables us to offer the extra finishing process that enables Potters to keep up its long standing all under one roof philosophy. Whatever the scale of your job and the intricacies involved, we will tailor our services to meet your exact needs. The result? An incredible finish, and guaranteed customer satisfaction!

Our Silkscreen Printing Process

Silkscreening is the process of passing durable inks through a porous fabric, creating a high-resolution sharp-edged single-colour image created from a stencil. The metalwork is then cured in an oven ensuring the ink adheres to the finished metalwork. Multiple colour images are created by incorporating multiple stencils onto one surface and cured after each process. One graphic and screen for each colour, It is ideal for flat graphics with a limited number of colours, as each colour needs to be silk screened separately. The more colours used, the more time it will take to silkscreen. However, this multi-stage process is something we regularly undertake at Potters and it is not uncommon for a four or five colour process being undertaken in the silkscreen department. Not sure if we can help you? Get in touch with a member of our team, and they will be able to tell you if silk screen printing is suitable for your particular application.

Fantastic Silk Screen Printing Results

Due to the self-levelling nature of applying silkscreen ink, it produces a smooth finish that is virtually indistinguishable by touch. Heavily textured finishes can degrade the screen print quality and are not advised. Small features, fine print and thin lines can look distorted on a rough surfaces. Best results are achieved on bare metal or smooth finish, lightly textured wet paint or powder coat, which are also both available as an in house process at Potters. We’ll be able to work with you to ensure a flawless end result. That’s why customers come back to us time and time again – because they know that we can deliver, no matter the task.

Contact Us Today

If you would like to know more about our silkscreening services, then please do get in touch with us today. We’d love to talk you through the silk screen printing process, and get the ball rolling as quickly as possible on your project.

Our Silkscreen Technical Specifications:

- Two screen printing stations

- Stoved or air dried inks

- Unlimited colour choice.

- Curing Oven

FAQ’s

Silkscreen printing is one of the most popular services that we offer, and we deal with a wide range of clients working on projects of many sizes and complexities. The advantages of silkscreen printing include the following:

- Long-lasting and durable

- Produces a great finish with vibrant colours

- Cost effective

- Smooth finish that is virtually indistinguishable by touch As you can see, silkscreen printing is a process that has so much to offer. To find out more about how it could be incorporated into your project, please get in touch with our team today.

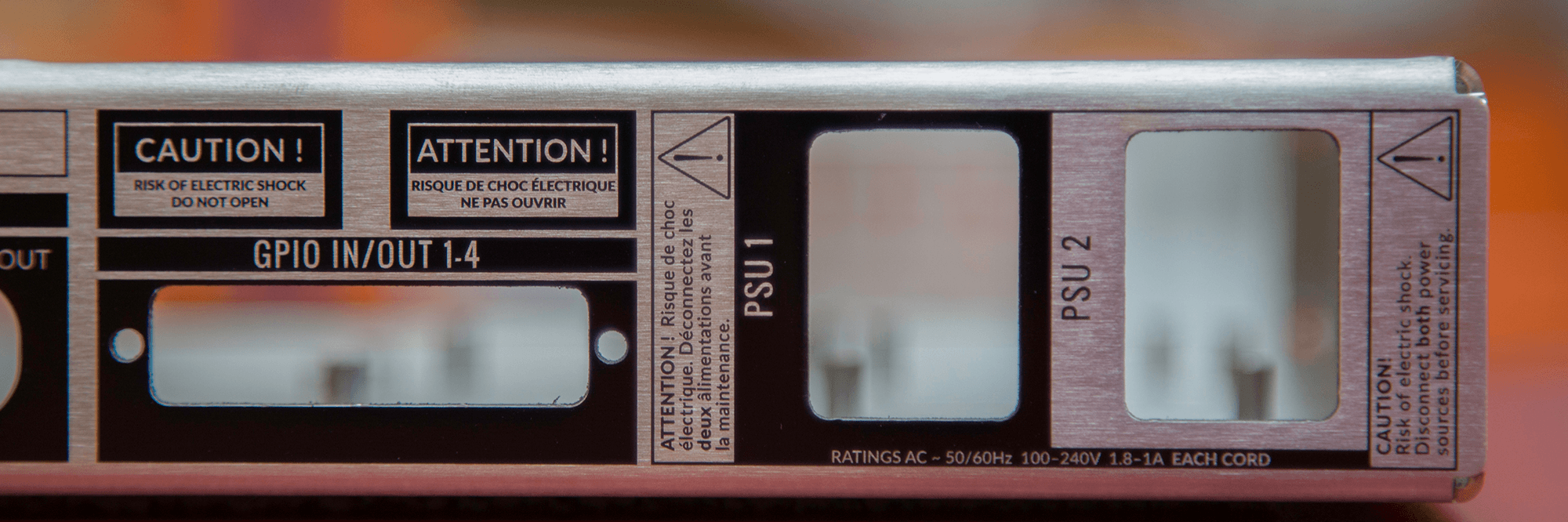

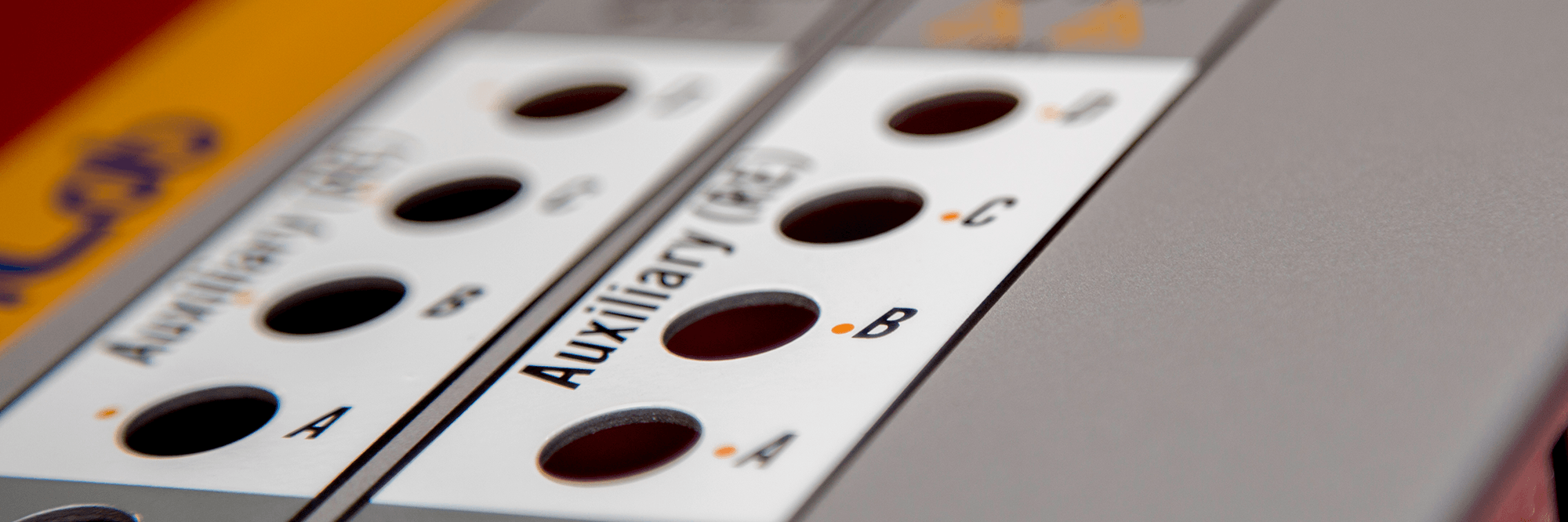

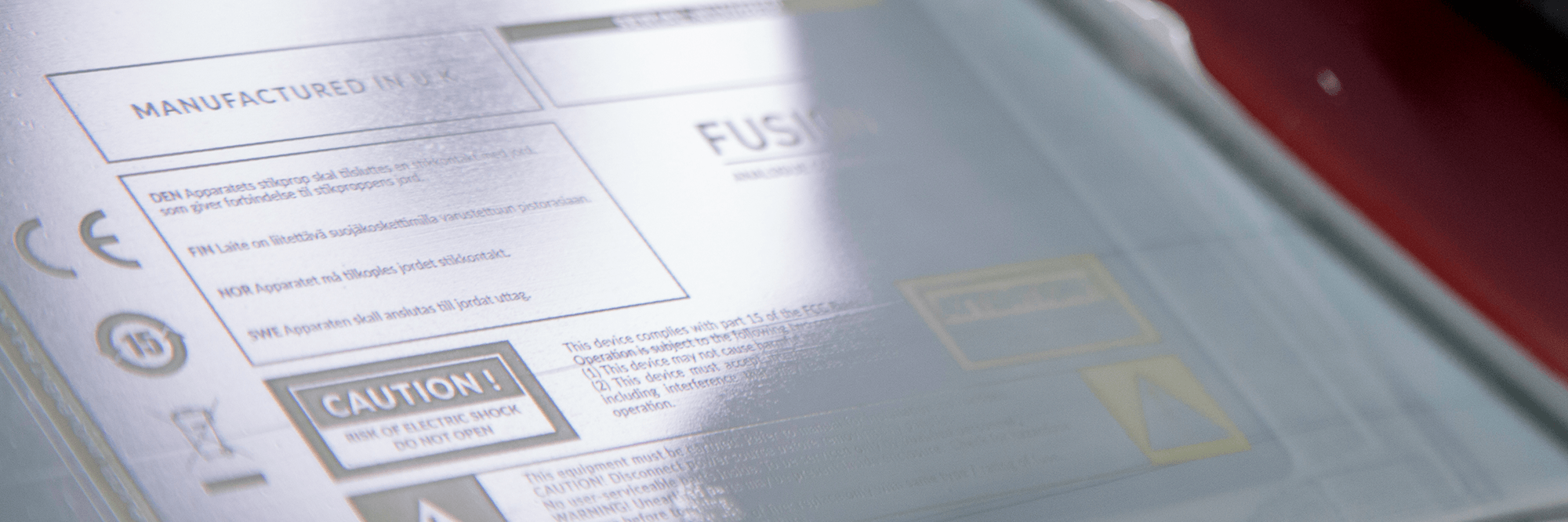

Silkscreening can be used for logos, control panel diagrams or operating instructions on the finished part. While transfers or labels can suffice, these are liable to damage and degradation over the lifespan of the product. Metal is used for it’s durability and if these text or graphical representations can be added directly to the metalwork, they can endure a higher degree of wear and tear and look far more effective.

This is entirely dependent on the silkscreen design itself. We use one graphic and screen for each colour, as each colour needs to be silkscreened separately. The more colours used, the more time it will take to silkscreen. We do regularly undertake multi-colour silkscreening here at Potters, with some designs consisting of four or five different graphics.