Metal Bushing

PEM Fitting at LL Potters

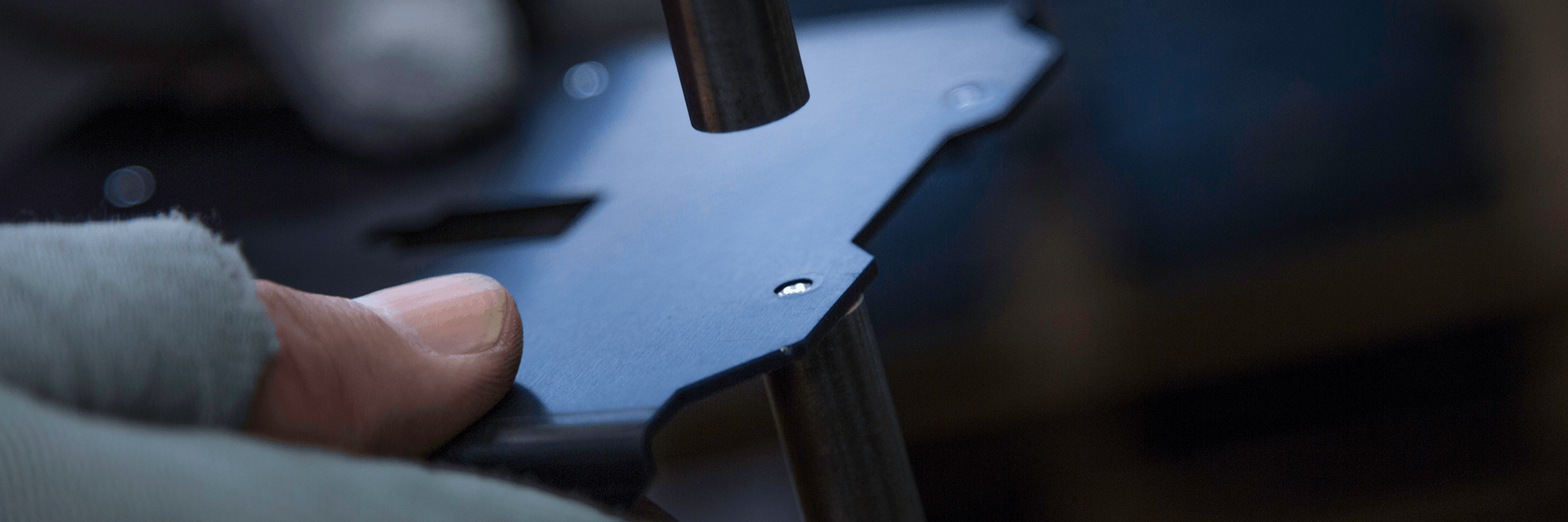

Offering customers unrivalled efficiency and high speed, all at highly competitive prices. We’re equipped with state-of-the-art Haeger fastener insertion systems. This is crucial for metal bushing as it allows us to complete jobs to the highest quality within the tightest of time frames.

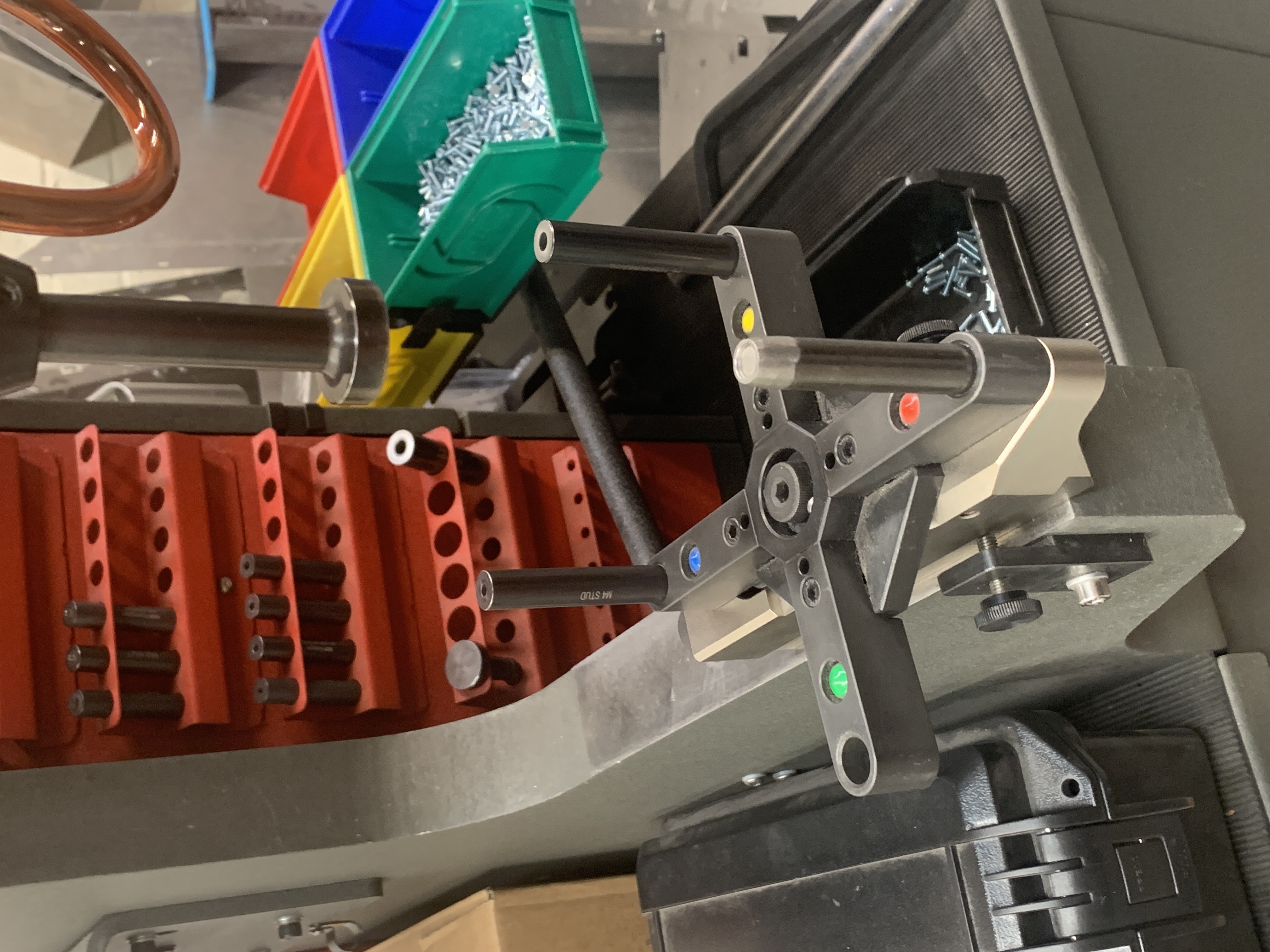

Our Haeger fastener insertion machines are set up for multiple configurations to allow us to cater to every aspect of your project. This includes PEM fitting because this allows us to meet your needs without delay.

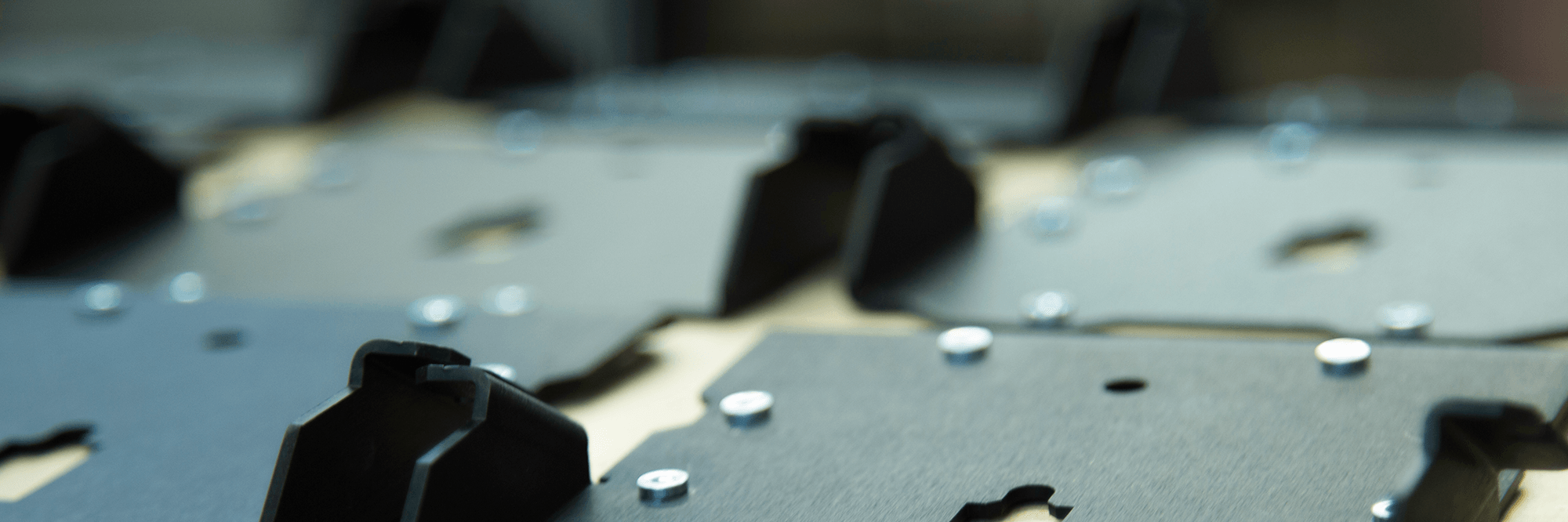

Our Multiple machines provide real flexibility and reduced setup times. We also hold a large stock of bushes and inserts, preparing us for various eventualities because we know that no project ever runs smoothly. Special requirements can be accommodated through in-house tool manufacture. Our experienced team is on hand to help you with all your metal bushing needs, allowing you to make sure you have everything you need to make your job a success.

Safe, dependable, and versatile. It’s easy to see why Haeger systems are the leading choice for metal bushings. We have multiple styles at Potters, including large brush load/unload support tables for bigger components.

Most of our bushing machines feature a multi-station option that fits four fastener styles in one setup. This is for single pick-up operations and more efficient throughput. We have plenty of years of experience working with these insertion machines. We will be able to expertly tailor our services to suit the needs of your project.

For more information about our PEM inserting services, contact our team today. They’d be delighted to answer your questions and provide you with all the information you need.

Metal Bushing Technical Specifications

5 x Haeger presses

Combination of 6 & 8 ton presses up to 24″ throat

Brush table load/unload for larger components.

What is PEM fitting?

PEM fitting refers to the insertion of PEM fasteners into metal components using specialised machines. At LL Potters, we use advanced Haeger fastener insertion systems for precise and high-quality PEM fitting, allowing us to handle various configurations and provide efficient service.

How does Haeger technology improve your bushing services?

Haeger systems provide unmatched efficiency and flexibility, allowing us to perform multiple fastener styles within a single setup. With multi-station options and reduced setup times, Haeger machines streamline the process for faster throughput, ensuring high-quality results within tight timeframes.

Do you have the capacity for large components?

Absolutely. We have large brush load/unload support tables for bigger components, ensuring safe and efficient handling of larger items. This feature is part of our commitment to offering versatile and dependable services.

How many Haeger presses do you have?

At LL Potters, we operate with 5 Haeger presses, allowing us to handle a variety of projects with high efficiency. These presses include both 6 and 8-ton machines with up to 24" throat capacity.

Do you accommodate special requirements?

Yes, we offer in-house tool manufacture to meet specific needs or special requirements for your bushing and PEM fitting projects. Our team is dedicated to tailoring our services to fit the exact demands of your components.