Graining & De-burring

Our Metal Graining and Finishing Services

If you have been looking for the leading providers of graining and de-burring, you have come to just the right place. We are LL Potters, and over the years we have made a name for ourselves as one of the industry experts in linishing, brushing and deburring metal. We work with clients in a wide range of industries, and can work to meet tight time frames and demands of varying scale and complexities. That’s why customers choose us time after time.

Why Opt for Graining and De-Burring?

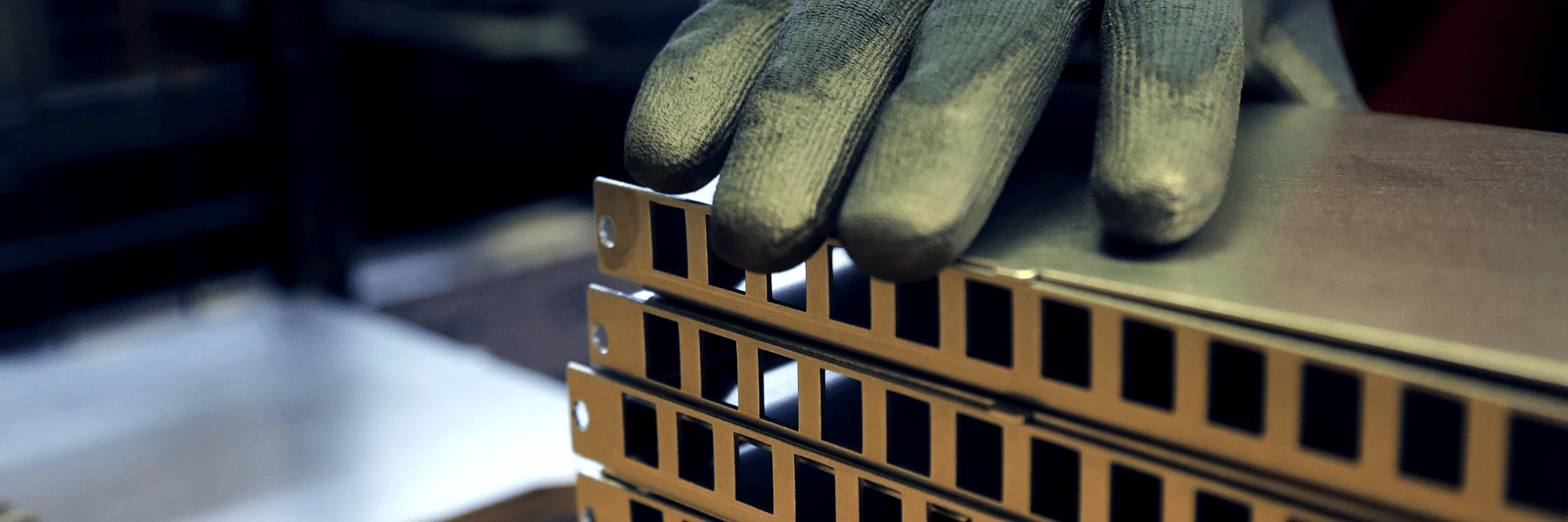

Our in-house de-burring and graining services are in high demand, and we are able to accommodate a growing number of clients. Brushed, grained or polished products have a much more uniform surface, which leads to a much more attractive, high-quality appearance. De-burring allows you to take that one step further, giving you the very highest standard of quality for your finished parts. De-burring edges leads to the best possible product uniformity, and improves the fit and overall look of each part.

Our two conveyorised grainers and Rotary brush deburring facilities provide:

- High quality grained finishes

- Consistency, batch to batch

- Cost effective production methods to suit individual requirements

- Ease of handling during product assembly

Technical Specifications

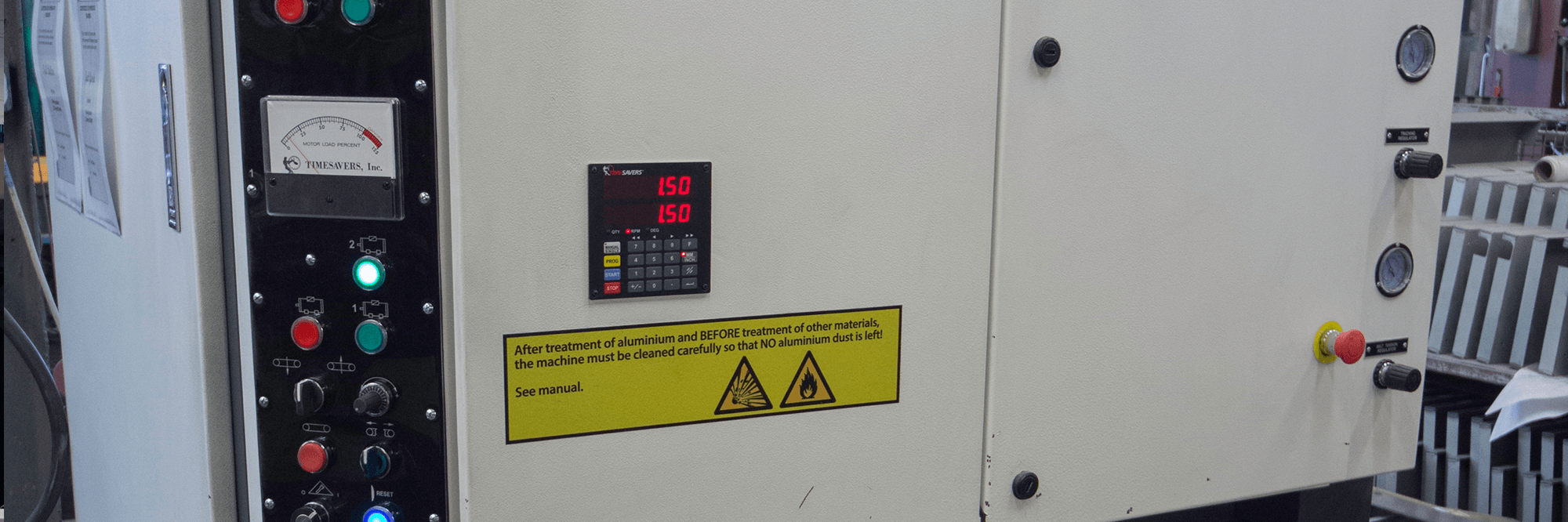

- 1 x Timesaver Grainer 900mm wide belt.

- Grind Master Grainer 150mm wide belt

- Timesavers 42RB Rotary brush deburring machine

- Vibratory De-burrer 1200mm bowl

Contact Us Today

If you would like to find out more about our graining and de-burring services, please do reach out to a member of our team today. They will be able to give you all the information that you need, so you can go on to work with us with total confidence. With cutting-edge equipment and years of experience at our fingertips, we’ll be able to deliver the best possible results for you and your business.

What is graining & deburring?

Metal that has been worked on using machines may be left with small imperfections or ‘burrs’ – which is where graining and de-burring comes in. These processes will see those imperfections removed and the surface of the metal transformed into a sleek, uniform part that is ready for a wide range of applications.

We can tailor our graining and de-burring services to suit the needs of a wide range of customers, working with you to ensure that you are happy with the finish of your metal parts. To find out more, please get in touch with our team today.

Why grain?

Graining is a practical method to remove surface irregularities whilst imparting a quality directional finish. The process is often required for aesthetic reasons by many of our customers to provide a high-level, uniform finish across the entire surface area of the component.

Sometimes it is sensible to use pre-grained material, which does incur a higher up-front cost. However, due to a components blank size and intricacy, graining the cut profile instead, as a secondary operation, can prove in many cases to be more cost-effective and provide better flexibility by avoiding paying for the scrap to be grained.

How does it work?

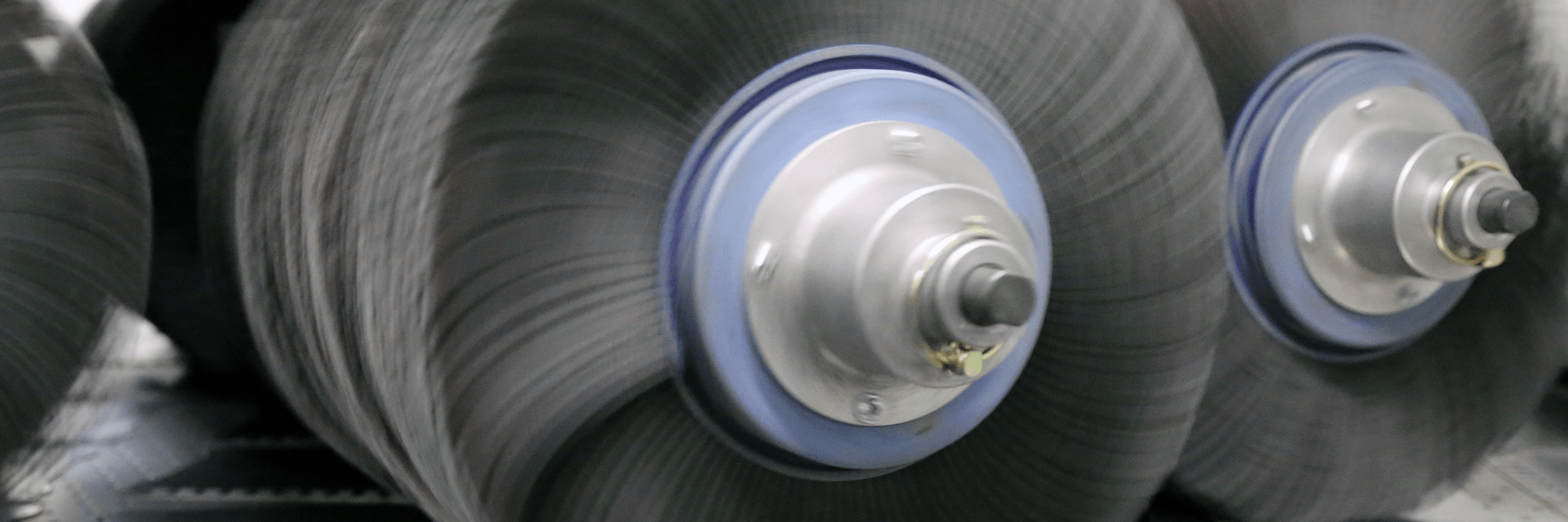

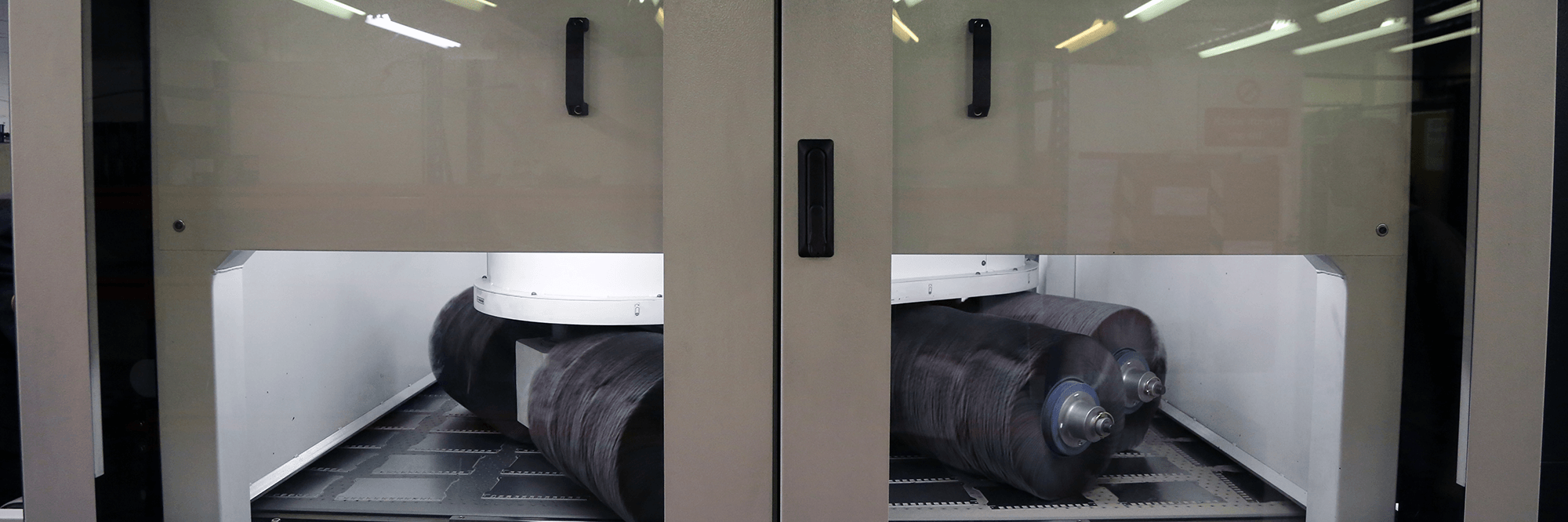

On our Timesavers 22 series 900 WW, components are placed onto a revolving conveyor, which then passes under two rotating graining belts moving in opposite directions until the desired finish is achieved. This kind of graining process is very clean, relatively silent and results in a regular even grain.

Depending on the thickness of the material being processed, the roller heights can be moved with very fine adjustment, we are able to change the position by 0.01mm ensuring a uniform finish across the entire component. The two graining belts used on the rollers are available in various grit finishes depending on the customers specifications.

If you would like to find out more about our graining and deburring services, please get in touch to tell us more about your particular project.