CNC Laser Cutting & Punching Specialists

Meeting Clients’ Needs With Our Laser CNC Machine

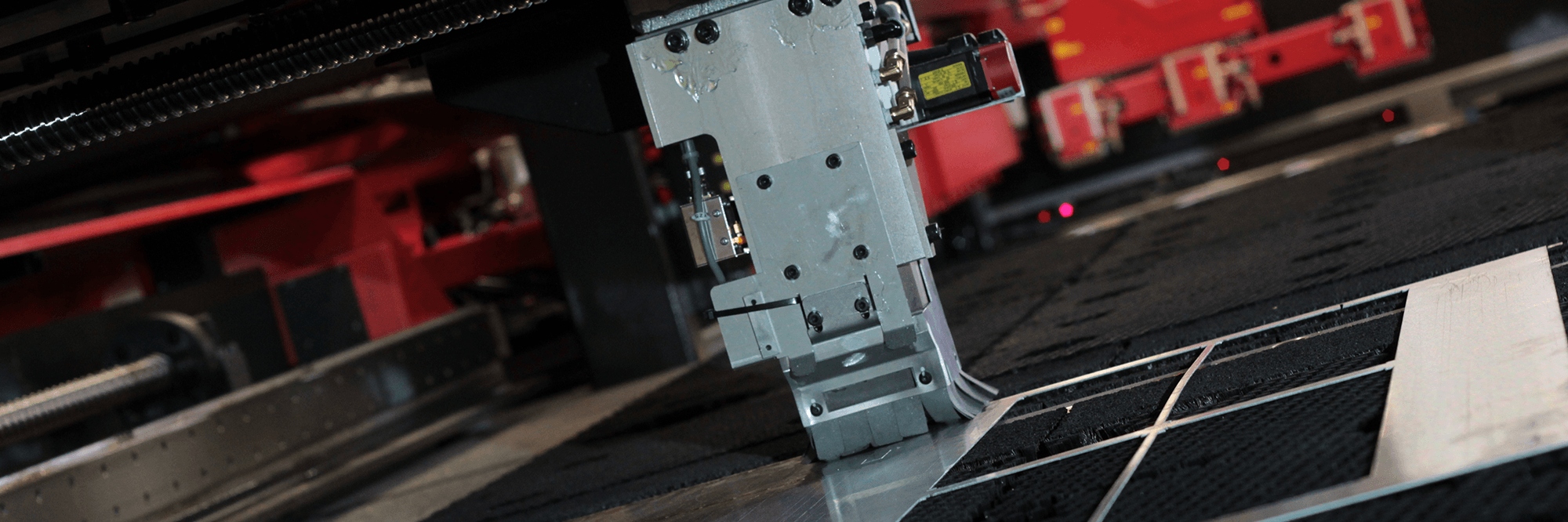

Automated Punch Laser Combination Machine

If you are looking for experts in CNC laser cutting and punching, you have come to just the right place. We are LL Potters, and we have plenty of experience when it comes to using punching and laser-cutting machines.

We have been sheet metal experts since 1964. Our first CNC machines were originally installed over forty years ago. Since then, we have continued using CNC laser cutting machines and state-of-the-art technology. This allows us to provide expert laser cutting solutions for a variety of different projects, allowing us to be the helping hand you need.

Our high standards have made us a firm favourite with clients in a wide range of sectors. You can count on us for accuracy and consistency, every time. We are capable of running 24 hours a day to provide efficient manufacturing for ongoing production.

So no matter the size or scale of your project, we’ll be able to meet the demand. We will also ensure that even the most pressing deadlines are met. With a wide variety of machines, as well as the latest technology we are on hand to provide a simple and effective solution.

CNC Laser Cutting and Punching

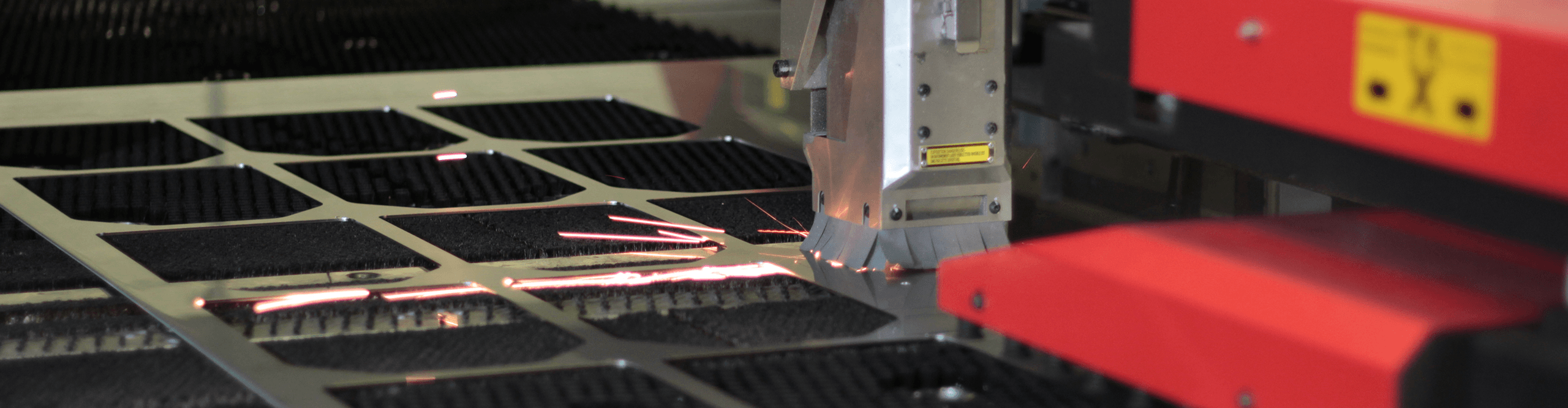

Through continuous investments, LL Potters have consistently been at the forefront of CNC punch/laser combination technology. These CNC laser cutting machines provide the best of both worlds allowing the ability to create several mechanical forms. This includes the likes of louvres, dimples and strengthening ribs or creating multi-hit perforated panels. This is all completed within the same process as high-quality, high-accuracy fibre laser cutting.

Our latest generation of punch/laser machines utilises fibre laser cutting technology. This allows the ability to cut a greater range of materials. This includes copper, brass and titanium with higher speeds and an even higher repetitive accuracy. This makes sure you are ensuring the same great results every single time.

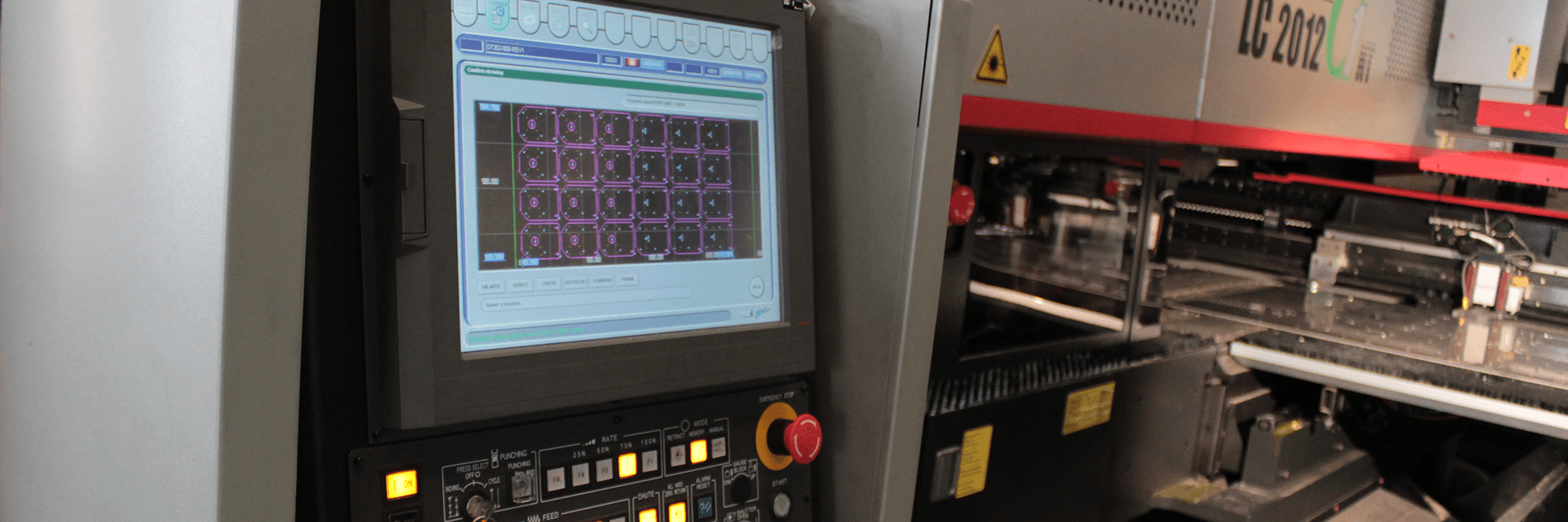

Our CNC punch/laser machines and the very latest programming software give us a great deal of flexibility. This has allowed us to improve our capacity for the amount of jobs that we can take on. As a result, we’re able to produce the components that you need cost-effectively and efficiently. This is ideal when it comes to helping you stay on budget and ensure that you remain on schedule.

Laser Cutting & Punching Technical Specifications

- Amada EML 2515AJ Laser/Punch Combination machine with automatic sheet load/unload.

- Maintenance-free servo electric punch action with energy recovery

- 30 Ton punching force, with high-speed punching and marking

- 3KW Fibre laser gives up to 70% electrical savings when compared with CO2

- Nitrogen generator for high-quality laser-profiled edges

- Extensive inventory of stock tooling

- Virtek laser Scanner for inspection of finished products

- Efficient handling via our vehicles

Contact Us Today

If you want to find out more about our CNC punching and laser cutting services, then please do get in touch. Reach out to a member of our team today.

They will be happy to answer any questions that you may have about CNC punching and laser cutting. We will be able to explore what we can do for you and your business in more detail. So what are you waiting for? Give us a call today.

How is metal plating done?

Metal plating is most commonly performed by immersing the metal in an acid solution with an anode electric current and cathode. The electricity causes negatively charged ions to move to the anode and positively charged ions to move to the cathode. This then covers the metal part in an even coating of metal. Metal plating often sees a lighter, lower-cost metal coated in a thin layer of more expensive metal such as nickel or zinc.

If you want to find out more about the process that we use, we would love to answer any further questions that you may have.

What types of plating are available?

We are here to offer our customers as much choice as possible, and you can take your pick from various different kinds of metal plating when you work with us. Here at Potters, we are able to offer Surtec, Zinc & Clear, Iridite, Nickel, Tin and various colours of Anodised plating finishes.

Each kind of metal plating has its own unique benefits, and will be suited to a specific range of applications. To make sure that you are choosing the correct metal plating for your project, we will be on hand to offer support and point you in the right direction.

Why is it important?

Why is metal plating important? Well, it allows you to introduce the qualities of a specific kind of metal to your particular part.

In addition, the lifespan of metal components without plating can be significantly reduced.

Metal plating adds a layer of non-corrosive and/or high-shine material to the surface of the metal substrate, making it much more resistant to rust, corrosion, and wear.

Can you handle large-scale production?

Yes! We have the capacity to meet high-demand production needs while maintaining efficiency and accuracy.

How energy-efficient are your machines?

We use 3KW fibre laser technology, which offers up to 70% electrical savings compared to traditional CO2 lasers.